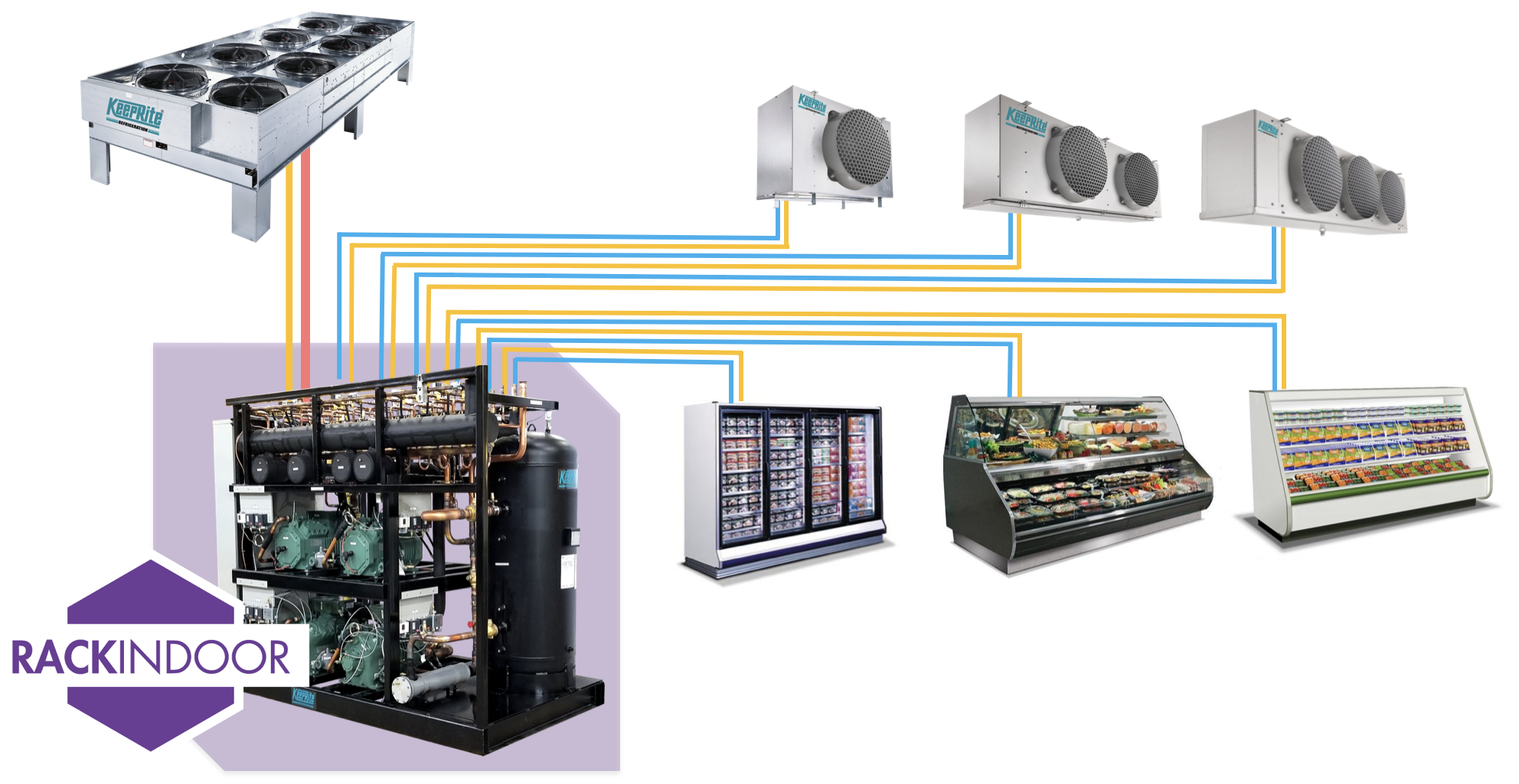

Rack Indoor

A Rack is an indoor Parallel Compressor Package for large horsepower compressors: large scrolls, semi-hermetics and screw compressors. It can fit a number of branch circuits and the electrical panels are spacious enough to house all the electrical components for the compressors, branch circuits and control boards.

The Rack offers the largest capacity in our offering.

Application

For applications calling for large horsepower compressors; large scrolls, semi-hermetics and screws - staged up and down using capacity controls to provide more efficient load matching. Supports all sizes of receivers and oil separators and accommodates a number of branch circuits and has spacious electrical panels – all in a heavy duty structural frame.

Features

- Welded and painted structural steel frame

- Scroll, semi-hermetic or screw compressors

- Compressors are protected with breakers

- Crankcase heater per compressor

- Phase monitor per compressor

- Operating lights and toggle switches for compressors

- Suction headers oversized to function as accumulators

- Catch-All suction filter per compressor

- Discharge thermostats per compressor

- Low and high pressure safeties per compressor

- Discharge vibrasorbers per compressor to ease in the removal of compressors

- Coalescent oil separator for high-efficiency oil separation

- Differential pressure gauge for indicating the state of the oil separator filter

- Discharge check valve to prevent back flow of gas from the condenser

- All suction pipes insulated at factory

- All suction pipes insulated at factory

- Charged with helium and leak checked

- Vacuumed below 500 microns and held for 24hrs

- Shipped with holding pressure of nitrogen

- Vibration pads to prevent transfer of vibration from the LINK (shipped loose)

- All components UL certified

Options

- Copeland, Carlyle and Bitzer compressors

- Horizontal or vertical receiver

- Branch circuits (air, electric and hot gas defrost)

- Mechanical subcooling

- Heat reclaim

- Mounted leak detector for all refrigerant types

- Electronic oil management system per compressor

- Cross over CPR/check valve for load capacity control betweensuction groups

- CPC, Micro Thermo, Danfoss and other controllers

- Run proofs for compressors

- Control boards for evaporator monitoring and circuits

- Mounted disconnect switch

- Mounted 3-way valve, head pressure regulating valves, flooding valves and other piping instruments

CAPABILITY/COMPATIBILITY